www.pinterest.com

www.pinterest.com Opening: Creating Your Own Oasis: Building a Shed with a Ceiling Fan Ever dreamt of a backyard escape, a workshop shielded from the sun, or a personal sanctuary with a gentle breeze? Building your own shed and installing a ceiling fan is a surprisingly achievable DIY project. This guide will walk you through each step, transforming your vision into reality.

Step 1: Planning and Preparation Before you even pick up a hammer, meticulous planning is crucial. This involves determining size, location, acquiring necessary permits, and gathering your tools and materials. Size and Location: Carefully consider the size you need based on the intended use. Ensure you have enough clearance around the shed and check for underground utilities before settling on a location. Mark out the area accurately. Permits: Contact your local building department to inquire about required permits for shed construction and electrical work. Failure to obtain necessary permits can lead to fines and delays. Tools and Materials: Prepare a comprehensive list of tools and materials. You'll likely need lumber for framing, sheathing, roofing materials, concrete blocks or a foundation, fasteners, a level, saw, drill, measuring tape, safety glasses, gloves, and the ceiling fan itself. Don't forget electrical wiring, conduit, and a circuit breaker for the fan.

Step 2: Foundation and Framing A solid foundation is essential for a long-lasting shed. Once the foundation is laid, you can begin the framing process. Foundation: Depending on the size and local codes, you can opt for a simple concrete block foundation, a gravel pad, or a poured concrete slab. Ensure the foundation is level and provides adequate support. Floor Framing: Construct the floor frame using pressure-treated lumber. Attach joists at regular intervals (typically 16 inches on center). Ensure the frame is square and level before attaching the floor sheathing. Wall Framing: Build the wall frames using 2x4 lumber. Include openings for doors and windows. Ensure the walls are plumb and square before attaching them to the floor frame. Secure the wall frames to each other at the corners. Roof Framing: Construct the roof rafters, ensuring the correct pitch for water runoff. Attach the rafters to the wall frames and install a ridge board for support.

Step 3: Sheathing and Roofing Sheathing provides structural support and weather protection. Roofing is the final barrier against the elements. Wall Sheathing: Cover the exterior walls with plywood or OSB sheathing. Nail or screw the sheathing securely to the wall frames, ensuring proper spacing between sheets. Roof Sheathing: Cover the roof rafters with plywood or OSB sheathing. Overlap the sheets slightly and nail or screw them securely to the rafters. Roofing: Install roofing felt or a waterproof membrane over the roof sheathing. Then, install your chosen roofing material, such as asphalt shingles, metal roofing, or wood shakes. Follow the manufacturer's instructions carefully.

Step 4: Electrical Wiring and Ceiling Fan Installation This step requires basic electrical knowledge. If you're not comfortable working with electricity, hire a qualified electrician. Wiring: Run electrical wiring from your house or a dedicated power source to the shed. Install a circuit breaker in the main electrical panel specifically for the shed's electrical circuit. Use appropriate gauge wiring for the expected load. Outlets and Lighting: Install electrical outlets and interior lighting as needed. Consider the placement of these fixtures for optimal functionality. Ceiling Fan Wiring: Run electrical wiring to the location where you plan to install the ceiling fan. Ensure the wiring is properly grounded. Ceiling Fan Installation: Follow the manufacturer's instructions to install the ceiling fan. Ensure the fan is securely mounted to a ceiling joist or a fan-rated electrical box. Connect the wiring according to the manufacturer's instructions, paying close attention to grounding.

Step 5: Finishing Touches Complete the shed with doors, windows, and any desired interior finishes. Doors and Windows: Install doors and windows according to the manufacturer's instructions. Ensure they are properly sealed to prevent drafts and leaks. Interior Finishing: Add insulation to the walls and ceiling if desired. Install interior paneling or drywall to create a finished look. Exterior Finishing: Paint or stain the exterior of the shed to protect it from the elements and enhance its appearance.

Conclusion: Enjoy Your New Shed! Congratulations! You've successfully built your own shed with a ceiling fan. You now have a comfortable and functional space to enjoy. Remember to inspect your shed regularly for any signs of damage or wear and tear, and perform necessary maintenance to ensure its longevity. Enjoy your new backyard escape!

Pine Ceiling Shed Rehab

www.pinterest.com

www.pinterest.com 15 Beautiful Shed Ceiling Ideas And Designs

plusmood.com

plusmood.com Ceiling Fan For Shed Lighting

www.pinterest.com

www.pinterest.com  monroesheddepot.com ```html

monroesheddepot.com ```html  www.gazebocreations.com

www.gazebocreations.com  www.amazon.com

www.amazon.com  www.homedepot.com

www.homedepot.com  www.walmart.com

www.walmart.com  kitchenaiding.com

kitchenaiding.com  www.mashed.com

www.mashed.com  www.wholesomeyum.com

www.wholesomeyum.com  www.homebazaar.com

www.homebazaar.com  askanydifference.com

askanydifference.com  www.homelandsskyline.lk

www.homelandsskyline.lk  www.mineralienatlas.de

www.mineralienatlas.de  www.freeimages.com

www.freeimages.com  stownest.com

stownest.com  www.pinterest.com

www.pinterest.com  www.homedepot.com

www.homedepot.com  thewanderlustkitchen.com

thewanderlustkitchen.com  yummyaddiction.com

yummyaddiction.com  coopcancook.com

coopcancook.com  shedbonanza.com.au

shedbonanza.com.au  www.shed-plans.biz

www.shed-plans.biz  www.walmart.com

www.walmart.com  www.sandatlas.org

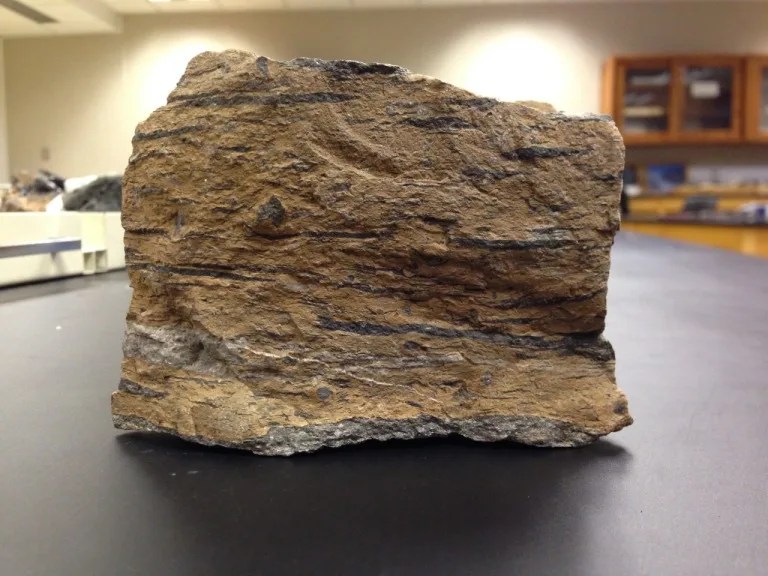

www.sandatlas.org  geologyscience.com

geologyscience.com  www.sandatlas.org

www.sandatlas.org  www.holdstorage.co.uk

www.holdstorage.co.uk  www.storageunitsdublin.com

www.storageunitsdublin.com  businessbolt.com

businessbolt.com  www.emisuite.es

www.emisuite.es  printables.king.us.com

printables.king.us.com  www.behance.net

www.behance.net  www.sobha.com

www.sobha.com